M/S. Girish Chandra Ghosh & G.G.S

FORMERLY M/S GIRISH CHANDRA GHOSH ESTD. 1874

Govt. Approved License Manufacturer / Repairer & DealerGovt. Approved Calibrator of Storage Tank of Petroleum, Chemical, Oil, Other Liquid Storage Tanks, Manufacturer of Weighing Machines and Complete Weighing Solution, Peg Measure. Leading Storage Tank Calibrator & Surveyor, N.D.T Inspection work, Inspection Survey & P.I Diagram in

India & Abroad

Tank Calibration Services with Precision

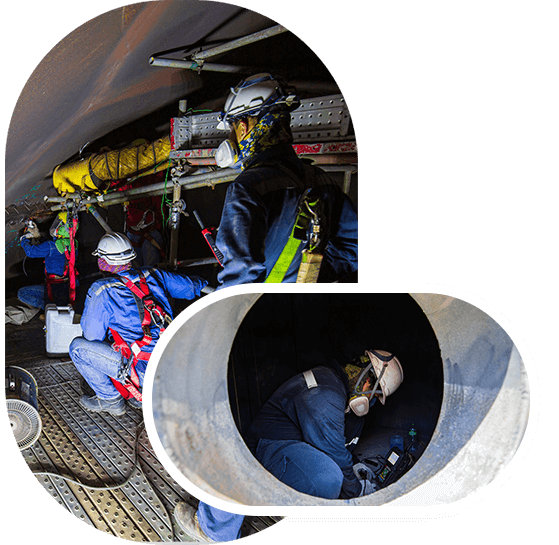

We are known as 'Girish Chandra Ghosh & G.G.S.' Over the years, we have earned a strong reputation as leading providers of Tank Calibration Systems. Our approach to tank calibration involves a team of highly skilled technical experts utilizing precision-calibrated instruments. We take pride in offering prompt and accurate services, evident from our successful track record in tank calibration.

Our dedicated professionals are well-versed in their respective domains. This is why they are able to handle critical tasks related to our trade. They ensure that all processes are carried out seamlessly. Before report are dispatched.

Read More...

Precision Tank Calibration Services: Ensuring Accuracy in Stock Management

Our tank calibration services are designed to provide accurate measurements and volumetric tables for both shore and ship installations, terminals, and tank farms. Whether you are in the oil and gas industry or managing distilleries, having precise data on your storage tanks is crucial for stock control and loss prevention.

Keeping your fuel tank calibration up-to-date is not just a necessity. It is a way to maintain trust with your customers and ensure smooth operations. We understand that efficiency matters. Our service focuses on delivering accurate calibration tables and survey reports with minimal disruption to your operations.

Having access to the latest technology and the safest calibration methods is your top priority. We are here to meet those needs and support your operational efficiency every step of the way.

We're India's Top Storage Tank Calibration Experts

Embracing technology and dedicated to excellence, we hold government approval as licensed storage tank calibrators. We are serving clients in the petroleum and various industries.

Why Work with Us?

We are a team of skilled engineers and technical experts known for providing affordable tank calibration services. To ensure the utmost accuracy, we use precise measuring instruments, advanced laser technology, and software developed in-house to analyze each tank individually.

Our quality management system follows ISO 9001:2000 2015 standards. We conduct rigorous quality checks at every stage. We handle government coordination professionally. We can also provide instant on-field computerized volume analysis for critical projects. When it comes to problem-solving and quick responses, our track record is exceptional.

Our Technical Expertise

No matter the complexity of the task, we excel in handling critical assignments. Whether it is a tank with a unique shape, tanks with intricate features like heating coils, floating roofs, or pressurized horton spheres, we ensure that precision is maintained throughout. Our engineering capabilities speak for themselves.

We have created advanced computer solutions that blend science and mathematics to provide precise storage tank calibration volume measurements. Plus, you can receive calibration and survey data in user-friendly formats, such as spreadsheets, on CD or via email. This is ideal for seamless integration with systems like SAP.

Looking For Advice?

The Advantages of Precise Tank Calibration

In a world where businesses need to watch their expenses closely, maintaining cost control in the handling of petroleum, LNG, LPG, chemicals, and oils is crucial. Whether it is storing, transferring, blending, or processing these substances, having accurate measurements is vital. Ensuring that storage and processing tanks are precisely calibrated is essential for meeting the highest product standards. A top-notch calibration not only guarantees high-quality products but also reduces complications with customers, government authorities, internal inventory management, and accountability.

Why Not Choose a Comprehensive Tank Calibration Solution?

As a reliable tank calibrator, weoffer a complete solution for distilleries, breweries, and beverage producers to accurately measure and verify tank quantities on-site. Our mobile flow rig is designed with a special focus on the drinks industry, ensuring precise tank calibration and the most accurate volume measurements.

Here's how it works: We flow a liquid medium through the system into the tank using a flow meter and batching alignments, providing the highest accuracy under controlled conditions similar to actual operations.

Our skilled service engineers can conduct tank calibrations right at your location. They deliver calibration certification and tank strapping tables. Plus, we can set up level instrumentation to verify volumetric levels.

Services include:

- Tank calibrations

- Flow verification

- Tank to tank measurement

- Batching

- Dosing

Accreditation & Memberships

Govt. Approved License Manufacturer / Repairer & Dealer

Register with Office of Zonal Director General of Foreign Trade | Register with EEPCINDIA. | MSME NSIC registered unit CRISILrated co. | UDYAM Registered | GEM Registered | CE Certified | ISO 9001-2015 certified company

Govt. Approved Calibrator of Storage Tank of Petroleum, Chemical, Oil, Other Liquid Storage Tanks, Manufacturer of Weighing Machines and Complete Weighing Solution, Peg Measure. Leading Storage Tank Calibrator & Surveyor, N.D.T Inspection work, Inspection Survey & P.I Diagram in INDIA & ABROAD

Should You Calibrate Regularly?

Even though we cannot see it, tank shells go through changes. Things like liquid pressure, temperature, and settling can affect their size. If you do not calibrate them or do it incorrectly, it can lead to volume differences and height references being off. Plus, if you make any changes or fix the tank, you should recalibrate it.

In India, it is mandatory to calibrate and certify storage tanks at least once every 5 years, according to the Directorate of Legal Metrology. Other countries also have their rules for calibration set by their government or special agencies.

Why Not Choose a Comprehensive Tank Calibration Solution?

As a reliable tank calibrator, we offer a complete solution for distilleries, breweries, and beverage producers to accurately measure and verify tank quantities on-site. Our mobile flow rig is designed with a special focus on the drinks industry, ensuring precise tank calibration and the most accurate volume measurements.

Here's how it works: We flow a liquid medium through the system into the tank using a flow meter and batching alignments, providing the highest accuracy under controlled conditions similar to actual operations.

Our skilled service engineers can conduct tank calibrations right at your location. They deliver calibration certification and tank strapping tables. Plus, we can set up level instrumentation to verify volumetric levels.

Which Standards Do We Adhere To?

When it comes to tank calibration in India, following standards is essential. In India, we hold licenses from the Directorate of Legal Metrology (Weights and Measures Department) in states where we are approved. We strictly adhere to their regulations and also follow BIS standards, which are recognized by Customs, Excise, and the Central Government CPWD department. Internationally, we align with various API and ISO standards for measurements, ensuring compliance with the specific requirements and regulations of each country. You can find more details on the standards and methods we use in our methods section.

Our commitment

With our wealth of experience, we aim to earn your trust by delivering our services responsibly and at an affordable price.

METHODOLOGY USED (International Standard : OIML approved)

(India is a member country of OIML)

- ISO 7507-1:2003 Petroleum and liquid petroleum products - Calibration of vertical cylindrical tanks - Part 1: Strapping method

- ISO 7507- 2 : 2005 Petroleum and liquid petroleum products - Calibration of vertical cylindrical tanks - Part 2: Optical-reference-line method

- ISO 7507- 3 : 2006 Petroleum and liquid petroleum products - Calibration of vertical cylindrical tanks - Part 3: Optical-triangulation method

- ISO 7507- 4 : 2010 Petroleum and liquid petroleum products - Calibration of vertical cylindrical tanks - Part 4: Internal electro-optical distance-ranging method

- ISO 7507- 5 : 2000 Petroleum and liquid petroleum products - Calibration of vertical cylindrical tanks - Part 5: External electro-optical distance-ranging method

For Vertical Storage Tank

- 2007-1974 : Method for Calibration of Vertical oil storage tanks

- 2008-1961: Method for computation of capacity tables of vertical oil storage tanks

Weights and Measure (Legal Metrology Department) Rules – Ninth A Schedule, Part No. II & III of the S.W.M. (General) Rules, 2011

For Horizontal Storage Tank

- 2009-1975 : Method for Calibration Horizontal and tilted oil storage tanks

- 2166-1963 : Method for computerisation of capacity tables for horizontal and tiled oil storage tank

- Customer Satisfaction

- Low Cost Efficiency

- Quality

- Saving Foreign Money by introducing World Standard in India with imported machinery

- Utilising Modern as well as Economic Technology

- Development of People

- A Team of Highly Skilled & Experienced Personnel

- Technology Development

We are committed to achieve and sustain leadership in Calibration of Storage Tank & Manufacturing.

Repairing in Weighing Machine & other allied service to customers as per acclaimed standards to meet their expectation in regard to quality & readability.

We are leading company in calibration & weighing world. We are committed to meet consumer quality service at a competitive price.

Our Featured Services

Tank Calibration

We excel at precisely measuring storage tank volumes. By doing so we ensure quantity control for various industries.

Ship Tank Calibration

Our calibration services extend to ship tanks, ensuring the accurate measurement of liquid quantities for safe and efficient maritime operations.

Tank Inspection

We conduct specialized surveys to assess tank settlements, roundness, and tilts. By conducting survey, we maintain consistent tank performance.

Weighing Scales Service and Supply

We provide comprehensive weighing scale services, including calibration, maintenance, and the provision of top-quality scales for accurate weight measurements.

Industrial NDT Consultancy

Our consultancy covers non-destructive testing (NDT) for industrial purposes. This is how we ensure the integrity and safety of vital equipment and structures.

Pipelines Survey

We conduct surveys on pipelines to provide valuable insights into their condition and performance. Our pipeline survey is designed to ensure the efficient transport of liquids.

Liquor Measures

We specialise in calibrating liquor measures ensuring precise dispensing and compliance with regulatory standards in the liquor industry.

Area of Services

We specialise in calibrating liquor measures ensuring precise dispensing and compliance with regulatory standards in the liquor industry.

The Storage Tank Calibration Process We Follow

We calibrate both horizontal and vertical land tanks, calculate pipeline volumes, and determine ship and barge tank volumes.

We take detailed assessments of the verticality of the wall, shape, roundness and roof & floor profiles. Tank calibrations adhere to strict international standards set by the International Standards Organization (ISO). We compile detailed volumetric tables for each tank, which can be customized to meet the client's specific needs. These comprehensive tables can use standard units of measure for size, volume, or both.

Why Not Choose a Comprehensive Tank Calibration Solution?

- Vertical Tanks

- Horizontal Tanks

- Spherical Tanks

- Cylindrical Tanks

- Double-wall Tanks

- Fixed Roof Tanks

- Floating Roof Tanks

- SDomed Roof Tanks

- Conical Roof Tanks

- LNG Tank Calibration

Tank Calibration and Measurement

- Tank Gauging

- Volume and Flow Measurement Services

- Liquid Calibration

- Liquid Storage Terminal Services

Awards / Recognition

2023

Award for Best Heritage Brand of the Year 2023 For Outstanding Contribution to Brand Development and Innovation From Universal Records forum (URF) Venue Eastern Metropolitan Club, on 4th March 2023.

2022

Heritage and Old Company Award of the year 2021-2022 from Bangla Hunt (Bengals largest media Digital network) Venue: Fairfield Marriot. (30th July, 2022)

2022

Award for Overall performance of the year 2021-2022 from Rotary Club Budge Budge Venue: Calcutta Club. (3rd August 2022)