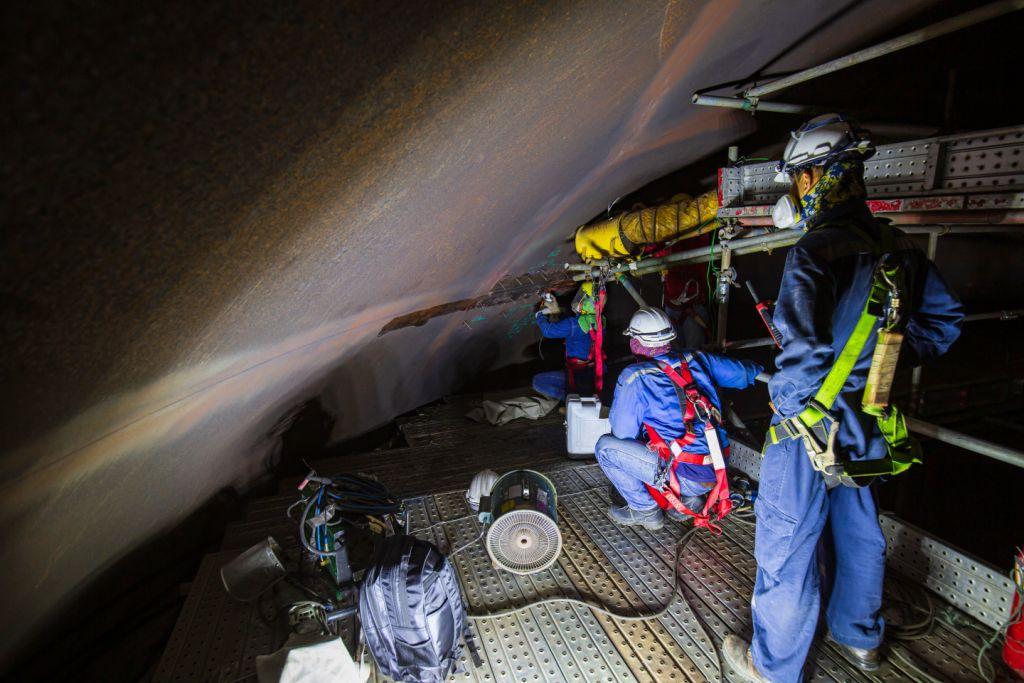

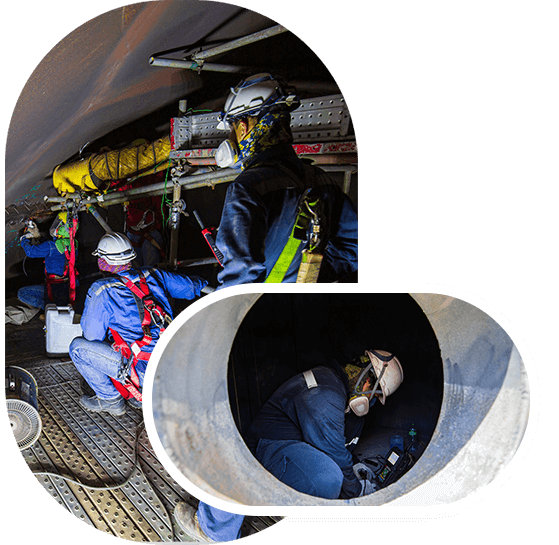

Expert Storage Tank Inspection and Maintenance Services

Regular tank inspection and maintenance of storage tanks is crucial for ensuring safety, environmental protection, and operational efficiency. It helps prevent leaks, structural failures, and compliance issues, reducing the risk of costly repairs and potential harm to the environment and personnel. Proper maintenance also extends the lifespan of tanks, ensuring they remain reliable and compliant with industry regulations.

At M/S. GIRISH CHANDRA GHOSH & G.G.S, we specialize in providing top-notch underground and aboveground tank pressure vessel inspection and maintenance services. We understand the critical importance of keeping your storage tanks in optimal condition to ensure safety, compliance, and operational efficiency. With our expert team and cutting-edge techniques, we are your trusted partner for all your storage tank needs.

Unveiling the Risks of Storage Tanks

Storage tanks, whether used for storing liquids, gases, or hazardous materials, come with inherent risks that necessitate careful management and maintenance. Several potential risks are associated with storage tanks:

Leakage and Spills:

One of the most immediate and significant risks is the possibility of leaks or spills. Whether due to corrosion, structural damage, or faulty seals, leaks can lead to environmental contamination, health hazards, and legal liabilities. Proper inspection and maintenance help detect and prevent all the risks before they escalate.

Structural Integrity:

Over time, storage tank structures can weaken due to factors like corrosion, erosion, and external forces. A structural failure can result in catastrophic consequences, including tank collapse, explosions, and fires. Regular water and petroleum product contained tank testing is vital to identify and address structural issues promptly.

Environmental Impact:

Storage tank failures can have severe environmental consequences. Leaked chemicals or hazardous substances can contaminate soil, water, and air, harming ecosystems, wildlife, and human health. Compliance with environmental regulations is essential to minimize these risks.

Fire and Explosion Hazard:

Tanks containing flammable substances pose a heightened risk of fires and explosions, especially if not properly maintained. Fire prevention measures, such as equipment grounding and the use of non-combustible materials, are crucial to mitigate these hazards.

What Causes Storage Tank Leaks?

Storage tank leaks can be attributed to various factors, with corrosion being a common culprit. Over time, exposure to moisture, chemicals, or harsh environmental conditions can weaken the tank's metal surfaces, creating openings that lead to leaks.

Inadequate maintenance practices can also contribute to storage tank leaks. Insufficient inspections and infrequent upkeep allow minor issues to escalate, making early detection and timely repairs crucial for leak prevention.

Structural damage, whether caused by accidents, impacts, or external forces, can compromise the tank's integrity and result in leaks. It's essential to ensure the tank's protection against potential sources of damage.

Faulty seals and gaskets that connect tank components or access points may degrade or fail over time, providing pathways for substances to escape. Regularly checking and replacing these components is essential for leak prevention.

Looking For Advice?

The Benefits of Routine Bulk Storage Tank Inspections

Routine bulk fuel tank inspections offer a wide range of benefits that are essential for ensuring safety, compliance, and operational efficiency. Here are some key advantages:

Early Issue Detection:

Regular tank settlement survey enables the early detection of potential problems, like structural issues. Identifying issues at an early stage allows for timely repairs, preventing costly and extensive damage.

Compliance Assurance:

Regulatory bodies often require storage tank owners to conduct routine inspections to ensure compliance with safety and environmental standards. Regular inspections help maintain adherence to these regulations, reducing the risk of fines and penalties.

Environmental Protection:

By detecting and addressing leaks or other issues promptly, routine inspections help prevent hazardous materials from contaminating the environment. This safeguards ecosystems, groundwater, and public health.

Enhanced Safety:

Regular fuel tank testing contributes to a safer workplace. Identifying and rectifying safety hazards and potential sources of accidents helps protect personnel and prevents workplace injuries.

Extended Lifespan:

Proper maintenance resulting from inspections can significantly extend the lifespan of storage tanks. This prolongs the useful life of the asset and reduces the need for premature replacements.

Tank Integrity Testing for Your Peace of Mind

Dye Penetrant Testing:

This method detects hidden flaws in tank seams and fittings, such as fatigue, erosion, wear, and cracking. It ensures early identification of potential issues, enhancing tank safety and reliability.

Visual Inspections:

These storage tank inspection methods uncover corrosion, rust, pitting, and cracks in storage tanks, addressing problems before they worsen, saving time and money.

Borescoping of Pipes and Tubes:

Tank inspection services inspect hard-to-reach areas within equipment, ensuring the integrity of often-overlooked pipes and tubes, enhancing overall tank performance.

Enhanced Safety:

Regular fuel tank testing contributes to a safer workplace. Identifying and rectifying safety hazards and potential sources of accidents helps protect personnel and prevents workplace injuries.

Extended Lifespan:

Proper maintenance resulting from inspections can significantly extend the lifespan of storage tanks. This prolongs the useful life of the asset and reduces the need for premature replacements.

Material Finish Verification:

Surface finish mapping verifies vessel surfaces' compatibility with specific processes, ensuring seamless equipment operation.

Material Thickness Verification:

This assessment confirms that storage tank components meet industry codes and safety regulations.

Storage Tank Inspection Approaches We Follow

Storage tank inspections are a critical aspect of maintaining the safety, reliability, and compliance of storage facilities across various industries. There are three primary approaches to conducting these inspections, each with its unique methods and advantages.

Risk-based Inspections:

This approach prioritizes water tank inspection efforts based on the assessed risk level of each storage tank, focusing resources on higher-risk tanks to enhance safety and compliance while optimizing maintenance costs.

Time-based Inspections:

Time-based inspections involve regular, predefined inspection intervals for storage tanks, ensuring routine checks and maintenance tasks are conducted at scheduled intervals, regardless of the tank's specific condition or risk level.

Non-destructive Testing (NDT):

NDT employs advanced techniques such as ultrasonic testing, radiographic testing, and magnetic particle testing to assess storage tank integrity without causing damage, providing valuable insights into structural health and corrosion levels.

Preventing Tank Leaks

Preventing tank leaks is essential for safety and environmental protection. Ensure your tanks stay leak-free with regular inspections, stringent maintenance practices, and immediate repairs when issues arise. Implementing a proactive strategy keeps your tanks in top shape and safeguards your operations.

Streamlining Tank Inspections through Digital Transformation

Managing underground storage tank inspection efficiently can be a complex task. Thankfully, you no longer need to handle it all manually. Instead of investing time, personnel, and money in endless paperwork, you can transition to digital inspections. This shift enhances safety, boosts efficiency, prevents major breakdowns, and promotes environmental conservation.

The Effects of Liquid Load on Steel Storage Tanks

If we consider a Steel Storage Tank like a plastic bucket, when we pour water into the bucket the plastic walls tend to expand then again come back. After we have filled the bucket full, we notice that the top rim of the bucket tends to be slightly elliptical instead of circular in shape. When we stir our hand inside water we notice that the bucket walls tend to wrap. Same thing happens with the large storage steel tank of oil, chemical. As it is daily filled in and out with oil, chemical there tends to be deformation of the tank walls, pressure on the tank floor and specially if it is a floating roof tank, the roof due to uneven foam seal gap. Also due to enormous weight of liquid pressure exerted on the tank bottom, the tank bottom tends to subside which can cause cracks in joints and make the tank tiled on one side gradually affecting centre of gravity.

Ensuring Tank Health and Safety

The tank can also tilt to one side due to uneven liquid head pressure. All this phenomenon is called out of roundness, tank tilt and tank floor settlement. If these are not studied and a detailed report made where you can repair, you can understand the catastrophe and safety/technical issues involved. It is this tank health that needs to be studied under API 653 B standard. To measure, study, analyze and make proper reports is very difficult. We have lots of experience in the field of tank calibration since 1983, which make us expert to study the tank health with our accurate instrument Total Station, Laser equipment and experienced engineers. After a few years of use, large tanks should always be studied for tank roundness, tilt and bottom settlement. We have mastered this technique of tank health checkup which can also include a detailed ultrasonic thickness report of tank floor and shell as floors can corrode over time, especially MS tanks. So, when tanks are decommissioned for any repair or cleaning, they should be studied as mentioned above. Just do the call or mail us. We are available to do this study around the world.